Hi All,

Yesterday I was pulling the camper out of the barn and did my normal walk around, twice no less, looking for, all jacks up, blocks out , steps up, all the normal things I do when taking the camper out of the barn. I slowly start pulling out and I hear a crunch… What?? :confused: backed up a foot and got out to look. Did 2 more passes around the camper and there is nothing in the way on the ground.

I am behind the camper and look up. Ohhhhh….:roll: The antenna is still up from doing work on the roof Friday night…. Let’s just say, a 12 foot high door is not enough for a Winegard crank up antenna to pass through uncrunched… Here all these years in the campground I always check this. Always. I have even caught other folks pulling out of their site and flagged them down, Hey your antenna is up! And Cindy even has a sign we hang on the crank handle to remind us when we are in camp the antenna is up. But the barn, there is no antenna up normally and well, I goofed…:-|

So now we have a new post on how to fix the problem… :) 12 years ago I bought an entire Winegard Sensor III antenna as the one we had never worked from when our prior camper was new. It seems in 2004 Winegard had a board issue in the roof head unit and they died early in their use. In our case, it never worked at all. So I bought the whole unit and just changed out the head. I kept the rest up in the rafters of 2 barns since then in case I needed the parts. Today I used them…

I will do this in pics as we do not have many antenna posts yet showing how these come apart.

I did not get a total pic of the damage, I was too flustered at the time but I did get a pic of the bent up head unit. See here. It popped the plastic covered off landing upside down on the roof and bent up the front bat wing. These pics are after I cranked it down which went really hard.

![]()

![]()

The damage to the head was not that much. The aluminum bat wing was pretty easy to straighten out and the plastic head was already off which I never knew how it came apart. Amazingly nothing in the head broke. I straightened everything out and put the head back together. Here are some pics of the plastic covers and the PC board.

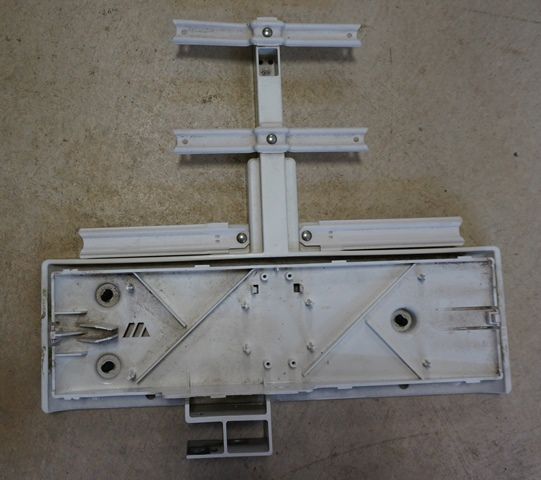

The inside of the bottom case cover

![]()

The inside of the top case cover

![]()

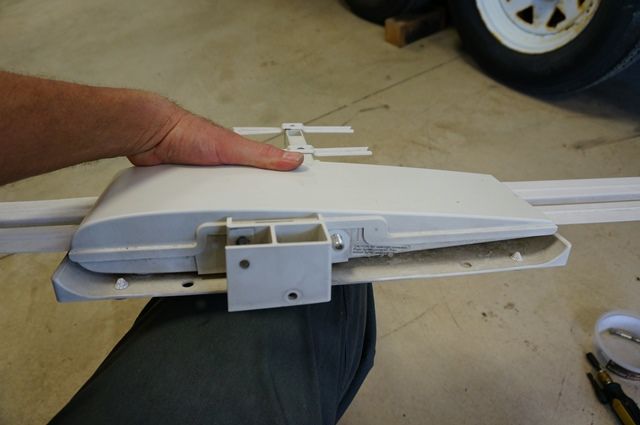

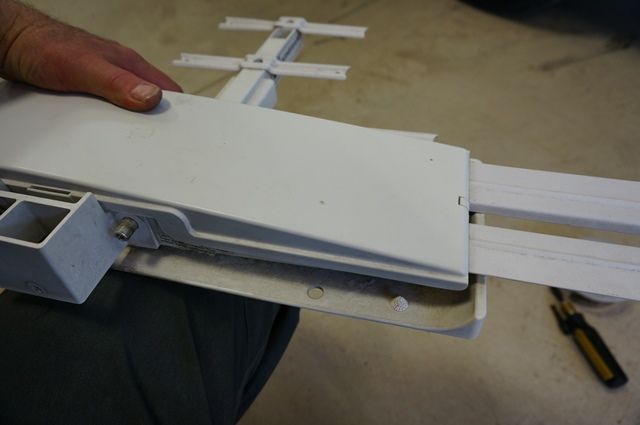

The bat wing straightened and installed back in the bottom case cover

![]()

The PC board

![]()

Here is how this top cover mates with the lower cover. They slide together and lock.

Place the top on the bottom cover but hold the top back to allow the tabs inside to align. You can see in the pic, the top cover is shifted to the left.

![]()

Now slide the whole top cover until it snaps in place to the right.

![]()

Here is the back snap lock. It is in the center of bat wind

![]()

Here is the front snap lock. It is in the center of bat wind

![]()

If you press those 2 snap locks in and push the cover to the back, then the cover comes off.

The entire head unit shot

![]()

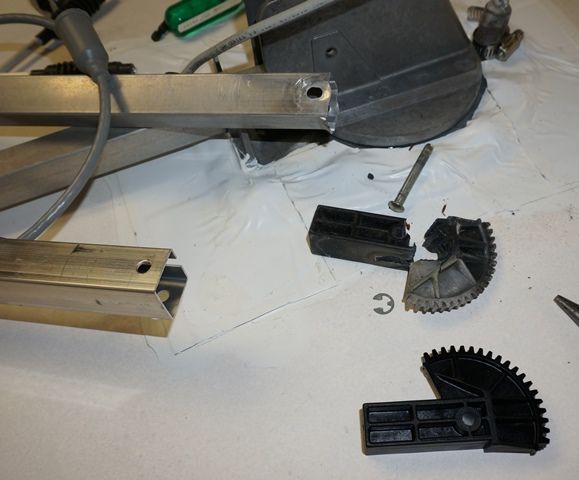

Next was to figure out why the head cranked up and down so hard. I could see the gear on the lift arm was broke.

![]()

This gear was cracked inside

![]()

Here is the old cracked gear next to the new gear and the damaged upper arm next to a new arm. It bent the end and elongated the pivot hole.

![]()

At this point I needed to make a decision if I was going to change the cable as it is threaded through the new arm with the connectors crimped on. This was originally built with no connectors on the ends of the cables and threaded through the arm, then crimped the fitting on. The old cable is 13 ½ years old, the outside of the cable is hard from sun damage and the cable weather boots are cracked. I have brand new cable already on the new arm I need to put on and I do not have to deal with the connectors. You have this half apart now, so just change the cable arm and pivot head. So that was the route I choose. Getting the old cable out and the new cable in through the roof took more time than anything else in this repair.

In order to take the rotating head off, you need to pull the crank arm inside and pull the worm gear out. This is not really hard, it took a few minutes.

The old ceiling crank.

![]()

You unloosen a hex head setscrew in the end of the handle and handle and the rotating knob comes out

Looks like this

![]()

Here is the ceiling portion left with the hex worm shaft sticking out.

![]()

You pull the hex worm shaft out up on the roof. Take off the black bushing nut to expose the worm shaft.

![]()

The unscrew the worm shaft up and out

![]()

Once the worm shaft is out, you go back inside and remove a plastic nut up in the bottom base of the unit to release the rotating head up on the roof. This takes a 15/16” deep socket and an extension to get up high enough. While I used a 1/2” drive socket, it was all I had deep enough to work. You really do not need one that heavy but it does work. The nut came out easy.

![]()

![]()

And the nut. Try and make sure you hold the socket steady so the nut come out with the socket and does not fall into the roof cavity. If it does, you need to go fishing for it. :roll: I did and caught it…:)

![]()

Once the nut is off, the rotating head will lift out easy.

![]()

Then to get the old cable out. This area can be a water intrusion area so Sunline pumped Dicro caulk in around the cable. The boot can crack and then water can get in. With the caulk around the cable, it helps stop if from getting in the camper.

![]()

I heated the Dicor gently with a heat gun as you do not want to affect the rubber roof and in my case, I have Eternabond over the mounting flange caulking I did not want to disturb. Then dig out the old caulk. Then go inside and fish out the cable from the roof cavity, there is a splice and unhook it.

![]()

In many cases you can just pull the cable up and out through the roof. In my case this was not simple as Sunline installed the antenna all pre-assembled. They did not leave enough room in the roof pad which holds the antenna base to allow the connector to pass through. This pics shows the cable and zero clearance for the connector.

![]()

I whittle out enough clearance to get the old cable out. Then I had to make sure I could get a cable with the connector on it, down from above and into the roof cavity. So I did a test run with the old cable to check the clearance.

![]()

![]()

Once I knew I can get the new cable down into the roof cavity, the rest of the install went pretty easy once again. I decided to use the new worm. They make these extra long to fit in most any RV roof. You need to cut it to the right length.

![]()

There are also lube points on the antenna. Silicone is the lube Winegard recommends. They want you to lube the seal the worm shaft goes through and the thin thrust washer pad that the rotating head pivots on.

I used food grade (because that is what I had) silicone grease on the worm shaft seal and the pivot head seal.

This is the worm shaft seal, the black ring in the center of the housing

![]()

Lubing the worm shaft area that turns in the housing worm shaft seal

![]()

The rotating head seal. The black quad seal in the middle

![]()

And then you place the thin thrust washer pad on and I used liquid silicone spray for this

![]()

Then the rotating head goes on next and you install the plastic nut inside the camper to hold it in place. There is a small thin plastic thrust washer that goes above the plastic nut. Don’t forget it. Do not over tighten as the head will not rotate. Test it before going forward that it will spin nicely when tightened up enough.

When the new rotating head is on, then insert the new worm shaft and fully seat it. You need to turn the shaft to thread in the worm to the lift arm gears.

![]()

And all the way down. You can rotate it from the top ofrgo inside and turn it. The black bushing cap nut will not fit right if the worm is not down far enough.

![]()

![]()

Then you can install the crank and rotating knobs inside. My old one has turned somewhat yellow from the sun over the years, so I changed it out to the new one

![]()

And now it looks better inside without the yellowing.

![]()

Then you can lift the arms to put the antenna head on and check the cable will flex correctly under full up and full rotation. There is this sticker on the side of the head about waterproofing of the cable connection.

![]()

I did as they stated and also wrapped a few turns of 3M Super 88 electrical tape over the cable fittings to help further waterproof it. If water gets in that connection, it is not good. My old Sensor II head had a boot over this area.

Once I know the cable lengths are good I push any excess cable back into the roof cavity. I also electrical tape built up the cable OD to create a caulk stop just below the roof line. I did not want all the caulk going down in the roof cavity as we only need it to seal the cable above the roof line.

The build up![]()

The cable set in place with the buildup on the bottom.

![]()

Then Dicor caulked the cable

![]()

And I added a stainless steel hose clamp over the cable. That boot has popped off before over the past and the clamp stops that and from the boot splitting from sun damage.

![]()

Here are 2 maintenance lube locations for silicone spray. The gear and the rotating disk thrust washer pad. The sticker on mine says do this twice a year.

![]()

You remove the black plug and spray liquid silicone in the hole and rotate the head full travel a few times to work the lube around.

![]()

And the finished unit

![]()

Point in all this… “remember” to lower the antenna, even in the barn… And if you break it, hope this post will helps someone in the future.

Thanks for looking.

John

Yesterday I was pulling the camper out of the barn and did my normal walk around, twice no less, looking for, all jacks up, blocks out , steps up, all the normal things I do when taking the camper out of the barn. I slowly start pulling out and I hear a crunch… What?? :confused: backed up a foot and got out to look. Did 2 more passes around the camper and there is nothing in the way on the ground.

I am behind the camper and look up. Ohhhhh….:roll: The antenna is still up from doing work on the roof Friday night…. Let’s just say, a 12 foot high door is not enough for a Winegard crank up antenna to pass through uncrunched… Here all these years in the campground I always check this. Always. I have even caught other folks pulling out of their site and flagged them down, Hey your antenna is up! And Cindy even has a sign we hang on the crank handle to remind us when we are in camp the antenna is up. But the barn, there is no antenna up normally and well, I goofed…:-|

So now we have a new post on how to fix the problem… :) 12 years ago I bought an entire Winegard Sensor III antenna as the one we had never worked from when our prior camper was new. It seems in 2004 Winegard had a board issue in the roof head unit and they died early in their use. In our case, it never worked at all. So I bought the whole unit and just changed out the head. I kept the rest up in the rafters of 2 barns since then in case I needed the parts. Today I used them…

I will do this in pics as we do not have many antenna posts yet showing how these come apart.

I did not get a total pic of the damage, I was too flustered at the time but I did get a pic of the bent up head unit. See here. It popped the plastic covered off landing upside down on the roof and bent up the front bat wing. These pics are after I cranked it down which went really hard.

The damage to the head was not that much. The aluminum bat wing was pretty easy to straighten out and the plastic head was already off which I never knew how it came apart. Amazingly nothing in the head broke. I straightened everything out and put the head back together. Here are some pics of the plastic covers and the PC board.

The inside of the bottom case cover

The inside of the top case cover

The bat wing straightened and installed back in the bottom case cover

The PC board

Here is how this top cover mates with the lower cover. They slide together and lock.

Place the top on the bottom cover but hold the top back to allow the tabs inside to align. You can see in the pic, the top cover is shifted to the left.

Now slide the whole top cover until it snaps in place to the right.

Here is the back snap lock. It is in the center of bat wind

Here is the front snap lock. It is in the center of bat wind

If you press those 2 snap locks in and push the cover to the back, then the cover comes off.

The entire head unit shot

Next was to figure out why the head cranked up and down so hard. I could see the gear on the lift arm was broke.

This gear was cracked inside

Here is the old cracked gear next to the new gear and the damaged upper arm next to a new arm. It bent the end and elongated the pivot hole.

At this point I needed to make a decision if I was going to change the cable as it is threaded through the new arm with the connectors crimped on. This was originally built with no connectors on the ends of the cables and threaded through the arm, then crimped the fitting on. The old cable is 13 ½ years old, the outside of the cable is hard from sun damage and the cable weather boots are cracked. I have brand new cable already on the new arm I need to put on and I do not have to deal with the connectors. You have this half apart now, so just change the cable arm and pivot head. So that was the route I choose. Getting the old cable out and the new cable in through the roof took more time than anything else in this repair.

In order to take the rotating head off, you need to pull the crank arm inside and pull the worm gear out. This is not really hard, it took a few minutes.

The old ceiling crank.

You unloosen a hex head setscrew in the end of the handle and handle and the rotating knob comes out

Looks like this

Here is the ceiling portion left with the hex worm shaft sticking out.

You pull the hex worm shaft out up on the roof. Take off the black bushing nut to expose the worm shaft.

The unscrew the worm shaft up and out

Once the worm shaft is out, you go back inside and remove a plastic nut up in the bottom base of the unit to release the rotating head up on the roof. This takes a 15/16” deep socket and an extension to get up high enough. While I used a 1/2” drive socket, it was all I had deep enough to work. You really do not need one that heavy but it does work. The nut came out easy.

And the nut. Try and make sure you hold the socket steady so the nut come out with the socket and does not fall into the roof cavity. If it does, you need to go fishing for it. :roll: I did and caught it…:)

Once the nut is off, the rotating head will lift out easy.

Then to get the old cable out. This area can be a water intrusion area so Sunline pumped Dicro caulk in around the cable. The boot can crack and then water can get in. With the caulk around the cable, it helps stop if from getting in the camper.

I heated the Dicor gently with a heat gun as you do not want to affect the rubber roof and in my case, I have Eternabond over the mounting flange caulking I did not want to disturb. Then dig out the old caulk. Then go inside and fish out the cable from the roof cavity, there is a splice and unhook it.

In many cases you can just pull the cable up and out through the roof. In my case this was not simple as Sunline installed the antenna all pre-assembled. They did not leave enough room in the roof pad which holds the antenna base to allow the connector to pass through. This pics shows the cable and zero clearance for the connector.

I whittle out enough clearance to get the old cable out. Then I had to make sure I could get a cable with the connector on it, down from above and into the roof cavity. So I did a test run with the old cable to check the clearance.

Once I knew I can get the new cable down into the roof cavity, the rest of the install went pretty easy once again. I decided to use the new worm. They make these extra long to fit in most any RV roof. You need to cut it to the right length.

There are also lube points on the antenna. Silicone is the lube Winegard recommends. They want you to lube the seal the worm shaft goes through and the thin thrust washer pad that the rotating head pivots on.

I used food grade (because that is what I had) silicone grease on the worm shaft seal and the pivot head seal.

This is the worm shaft seal, the black ring in the center of the housing

Lubing the worm shaft area that turns in the housing worm shaft seal

The rotating head seal. The black quad seal in the middle

And then you place the thin thrust washer pad on and I used liquid silicone spray for this

Then the rotating head goes on next and you install the plastic nut inside the camper to hold it in place. There is a small thin plastic thrust washer that goes above the plastic nut. Don’t forget it. Do not over tighten as the head will not rotate. Test it before going forward that it will spin nicely when tightened up enough.

When the new rotating head is on, then insert the new worm shaft and fully seat it. You need to turn the shaft to thread in the worm to the lift arm gears.

And all the way down. You can rotate it from the top ofrgo inside and turn it. The black bushing cap nut will not fit right if the worm is not down far enough.

Then you can install the crank and rotating knobs inside. My old one has turned somewhat yellow from the sun over the years, so I changed it out to the new one

And now it looks better inside without the yellowing.

Then you can lift the arms to put the antenna head on and check the cable will flex correctly under full up and full rotation. There is this sticker on the side of the head about waterproofing of the cable connection.

I did as they stated and also wrapped a few turns of 3M Super 88 electrical tape over the cable fittings to help further waterproof it. If water gets in that connection, it is not good. My old Sensor II head had a boot over this area.

Once I know the cable lengths are good I push any excess cable back into the roof cavity. I also electrical tape built up the cable OD to create a caulk stop just below the roof line. I did not want all the caulk going down in the roof cavity as we only need it to seal the cable above the roof line.

The build up

The cable set in place with the buildup on the bottom.

Then Dicor caulked the cable

And I added a stainless steel hose clamp over the cable. That boot has popped off before over the past and the clamp stops that and from the boot splitting from sun damage.

Here are 2 maintenance lube locations for silicone spray. The gear and the rotating disk thrust washer pad. The sticker on mine says do this twice a year.

You remove the black plug and spray liquid silicone in the hole and rotate the head full travel a few times to work the lube around.

And the finished unit

Point in all this… “remember” to lower the antenna, even in the barn… And if you break it, hope this post will helps someone in the future.

Thanks for looking.

John